A brand new member to our club, Dennis Fuge introduced himself and his long experience in woodturning with a great demonstration! While his main focus was to give us ideas on how to use metals and resins to make our wood turnings "POP", Dennis provided a little background on himself and his woodturning.

Dennis hales from South Africa, has traveled the world and now lives in Pennsylvania, but has had one constant- turning. This is his first turning, made in his compulsory shop class. While his instructor didn't give him good grades, we all thought it was a great start!

Dennis started the demonstration with a little quiz on wood identification. It proved to be quite a challenge for the group. The woods varied from Apple to Lemon, Black Walnut to Catalpa and Kentucky Coffee, both in their natural state as well as a unique turning from each.

Here is one of his signature pieces that demonstrates how he uses different materials to make what might be ordinary, become special- he's combined Apple, Lemon, Walnut and Copper all into one piece.

By using various combinations of metal tubes, wires, nails and epoxy, Dennis showed us how he fabricated the novel inserts for his turning and how he added them to his turnings.

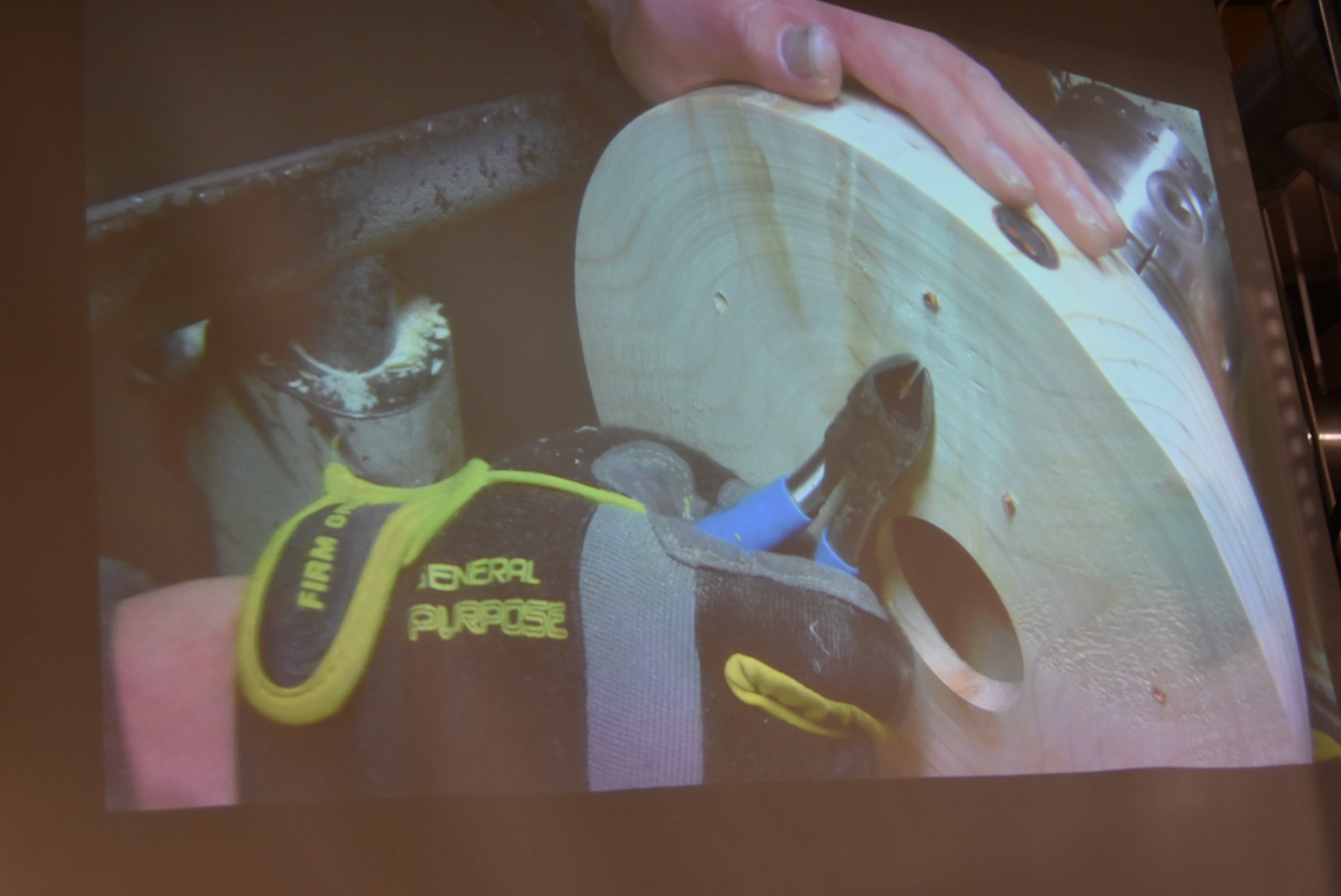

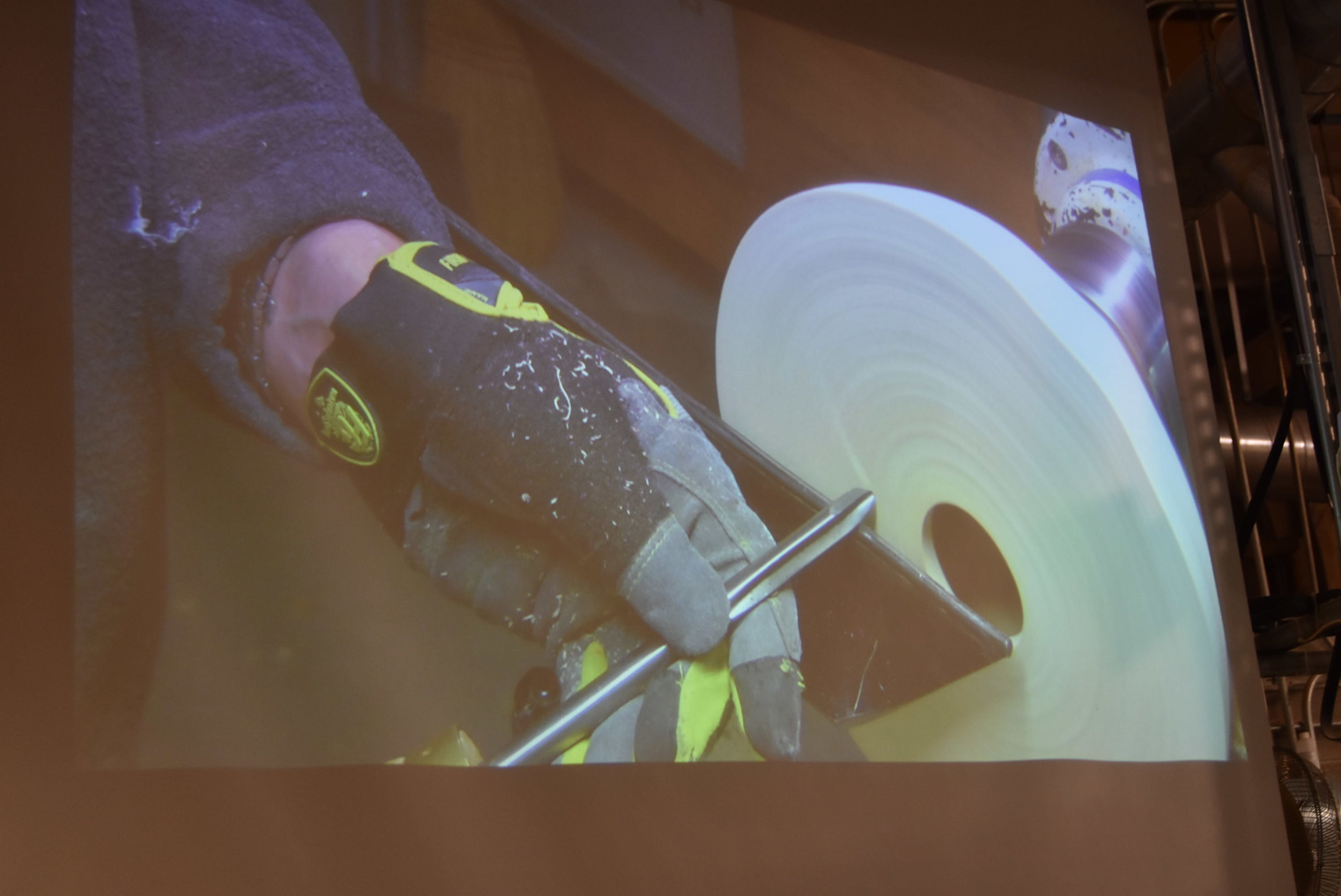

Dennis brought a partially hollowed vessel, put it on the lathe, trued it up with a bowl gouge, and then drilled several sockets with a Forstner bit to hold the "Smiley Faces" he inserted with the help of some CA glue. Using a regular bit, he drilled several holes into the face of the vessel and hammered in copper rods he purchased from Home Depot. If these fit tight, no glue is needed.

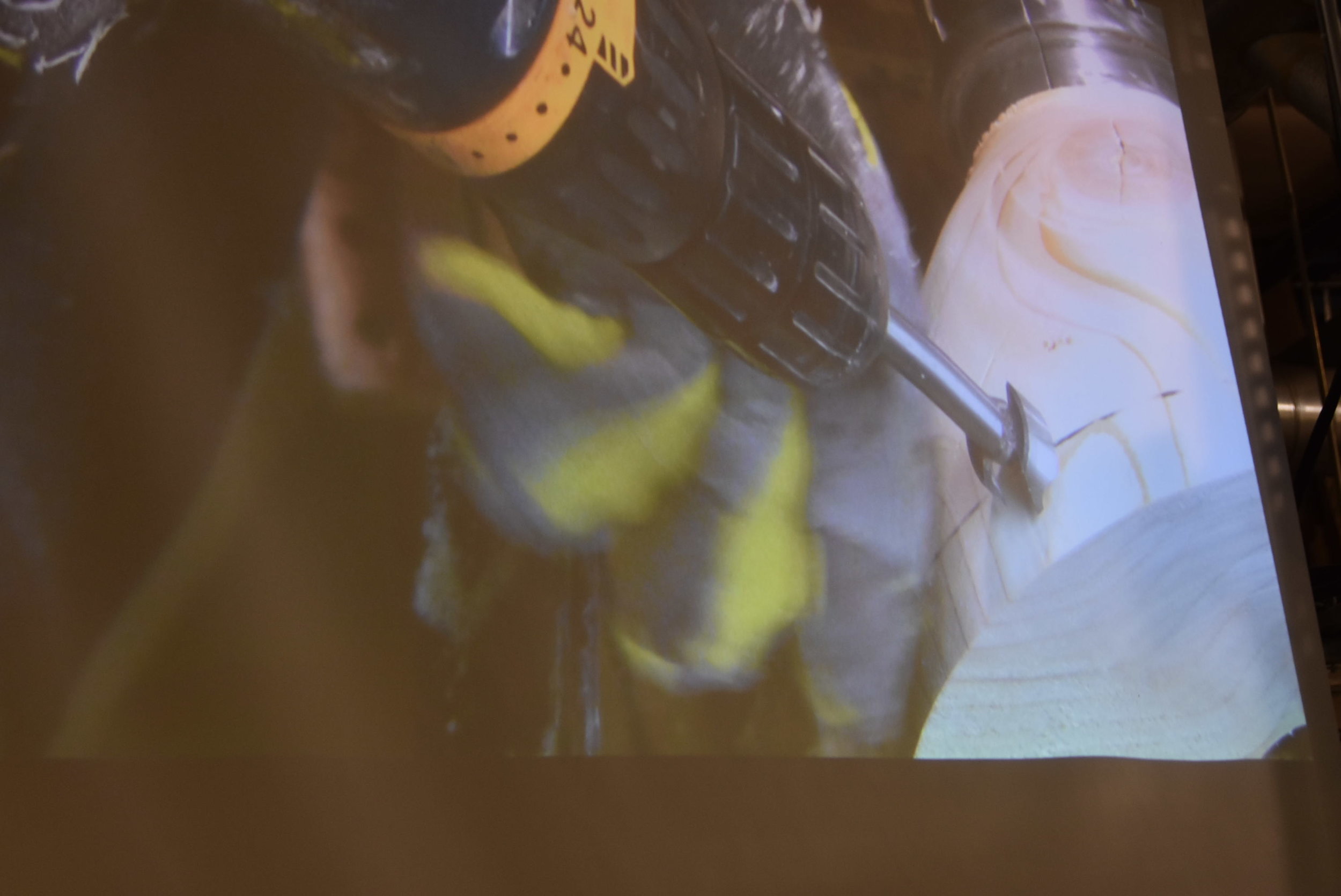

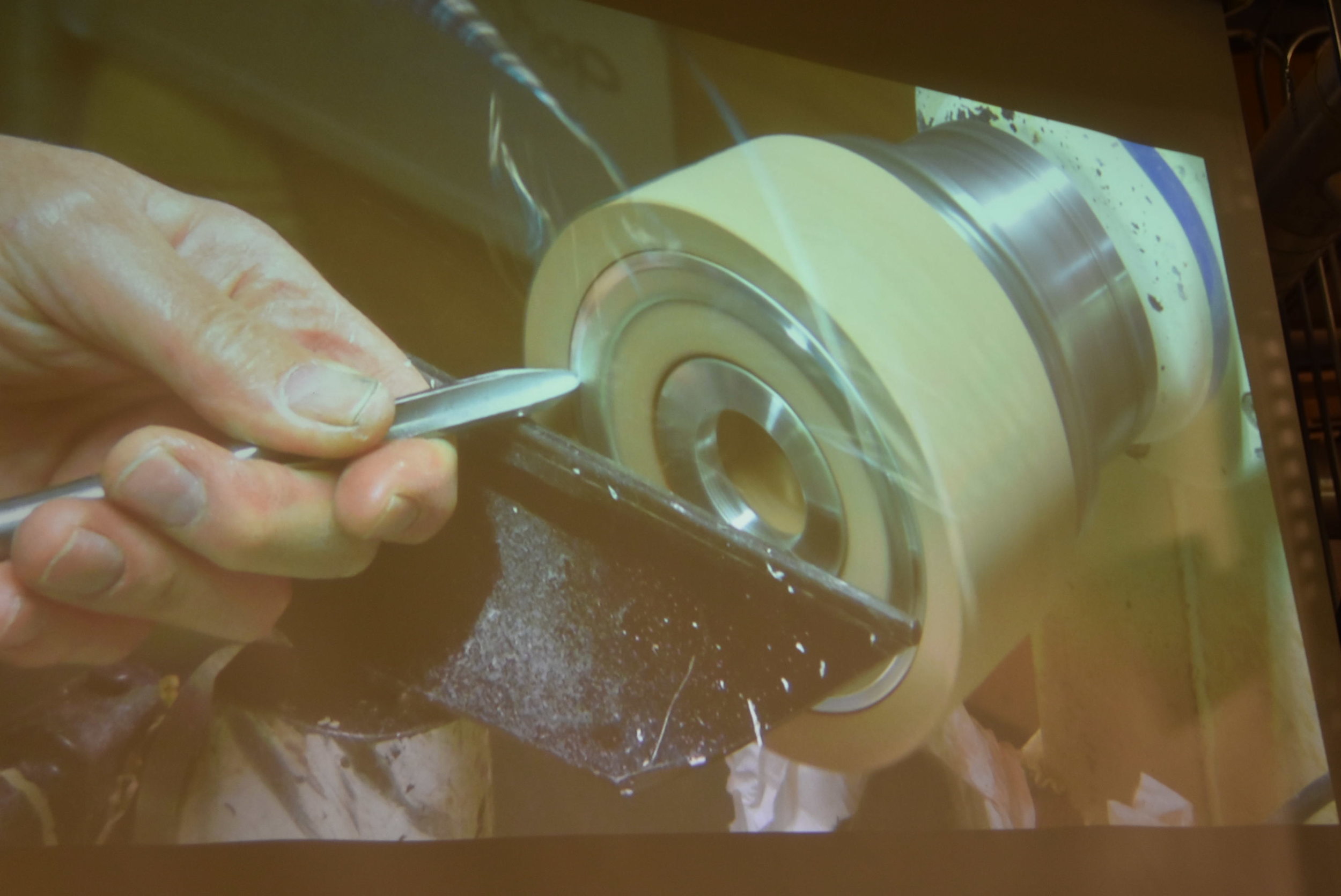

Now's the tricky part, cleaning up these metal bits sticking out from an otherwise smooth surface! Dennis trims the rods with the help of diagonal cutters, but then uses a 1/4 inch bowl gouge to bring them flush with the surface. He does this cutting by first finding the projecting metal by running the tool backwards until the bevel finds the rod, then lightly cuts by moving the tool forward. He uses the same technique to cut the "Smiley Faces" flush.

Dennis also likes to add character by using a wire brush to remove the summer growth. He warns that this technique doesn't relieve you from the task of first creating a smooth and well sanded surface. Dennis also suggests that the growth rings can be chased with the wire brush to further enhance the effect.

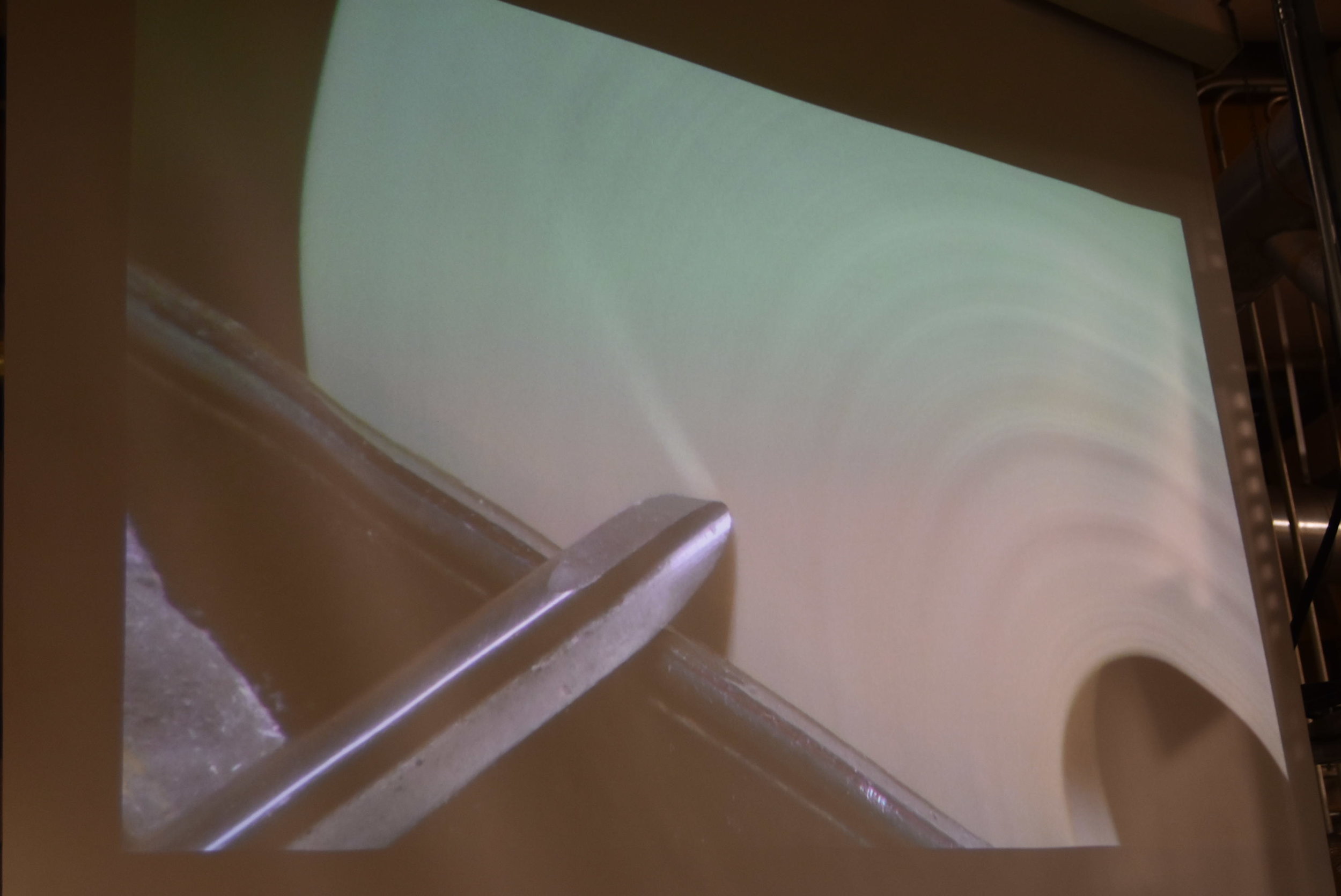

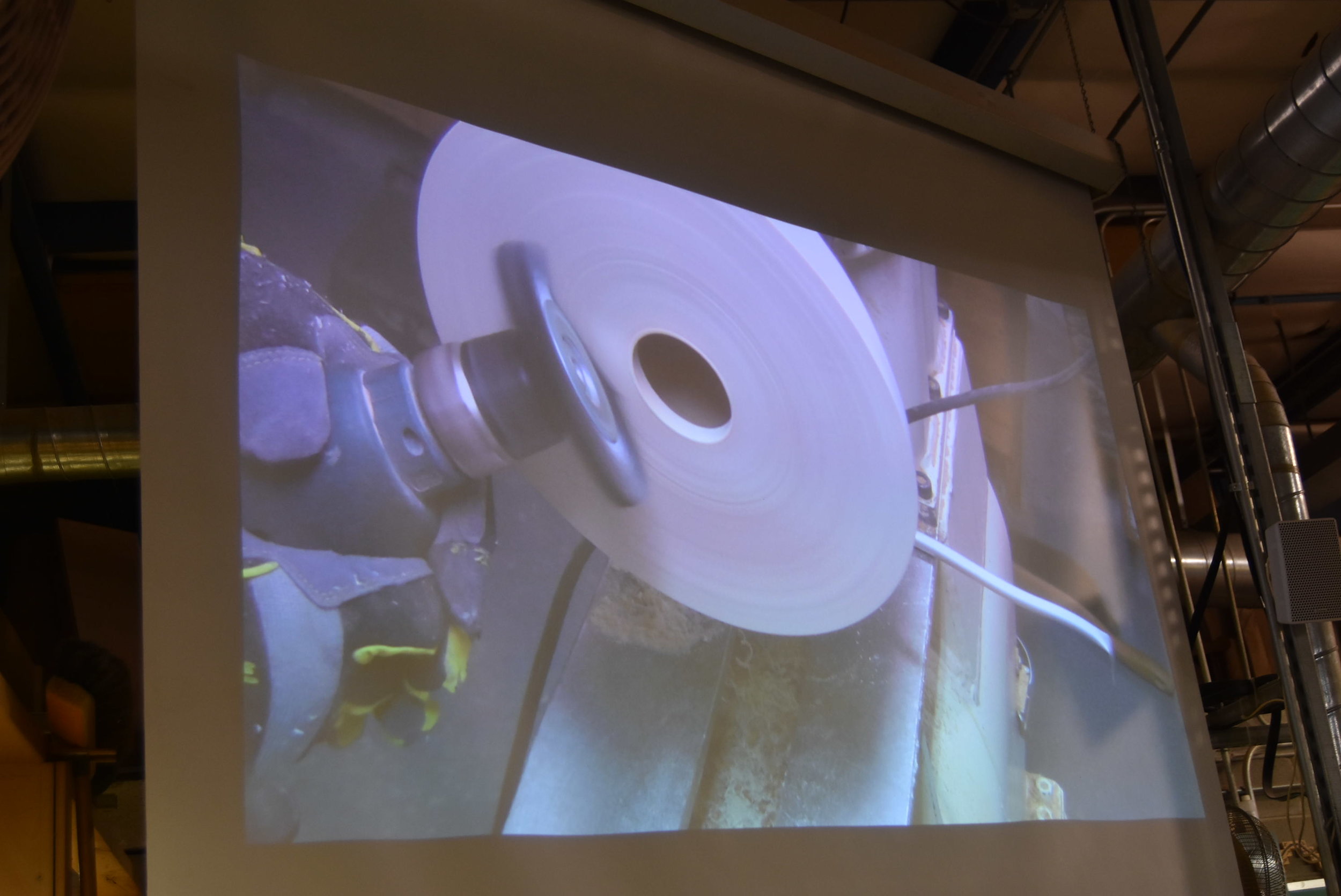

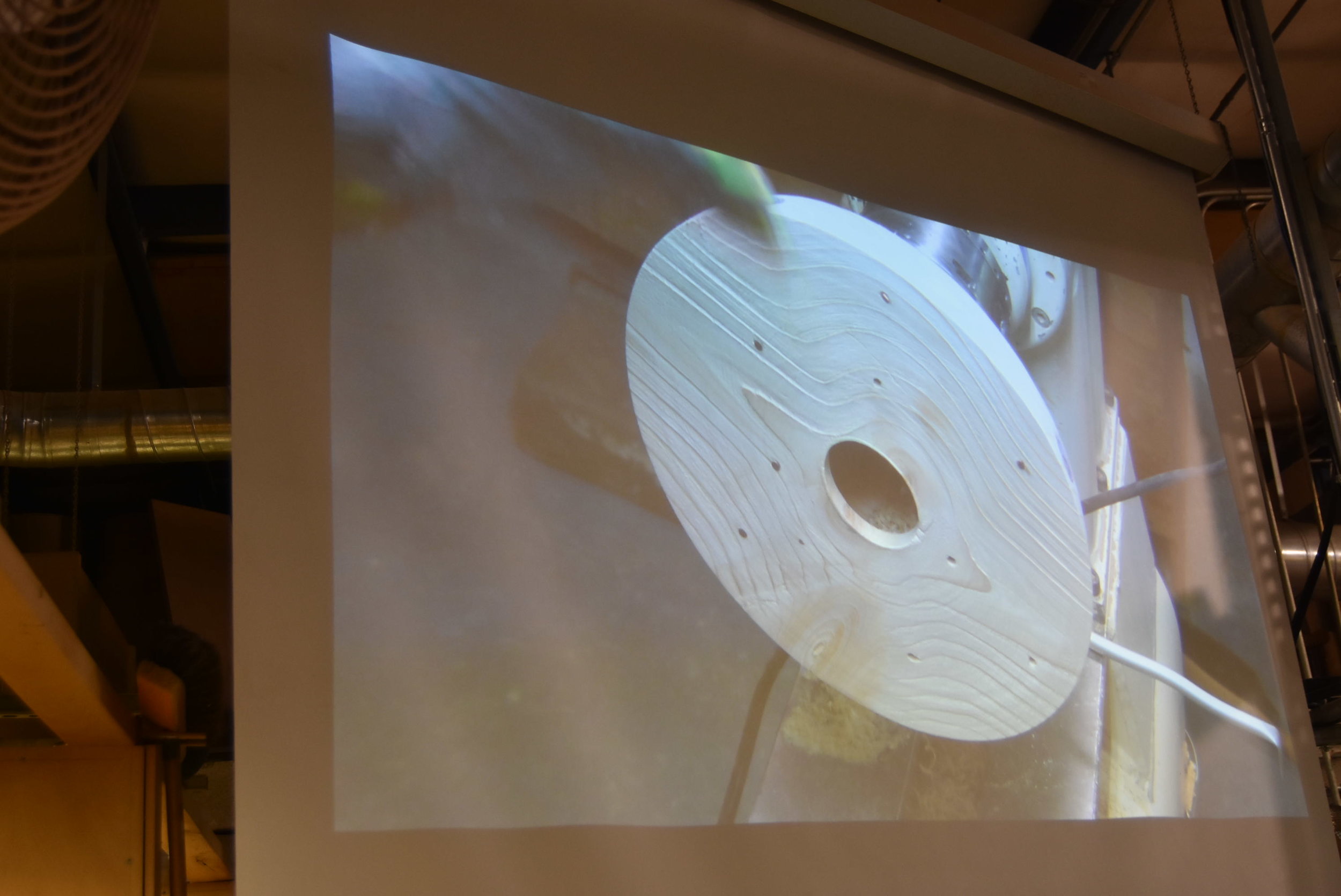

After showing us how to use colored epoxies, Dennis showed us how to cast and turn pewter! While he melted pewter scraps over a propane burner, Dennis turned a wooden mold. He then just poured the pewter in (yes the mold scorches from the heat), and after it cooled, he turned it to the desired size and was ready to insert it in the desired piece! Pretty neat!